FPG-LT Coffee Bag with Gas-filled Overwrap Packaging Machine

Options

●Weighing System (Load-Cell Weigher, Auger Filler etc.)

●Poking Device for Sub-Hopper

●Slide Doser Vibrator

●Chute Knocking Device

●Various Size of Chutes (120 mm, 140 mm, 160 mm, 180 mm etc.)

●Discharge Device of Defective Product

●Date Printer

Coffee Bag with Gas-flled Overwrap Packaging Machine

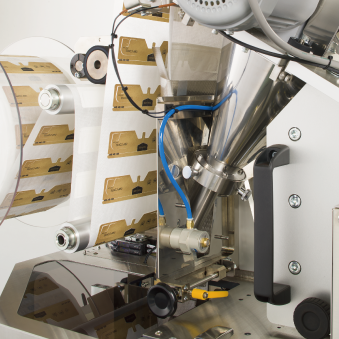

This is the upgraded model of the FPG-T1,

which is our standard drip coffee bag packaging machine.

●The new design is easier to maintain and operate.

●Multi-functional machine with the ability to pack drip coffee bags and tea bags.

●Nitrogen gas-filling prevents oxidation. Every single sachet can keep the taste and aroma fresh right before drinking.

(Nitrogen Gas-Filling Device is included with Standard Specification)

●Capacity up to 60 bags/min.

![]()

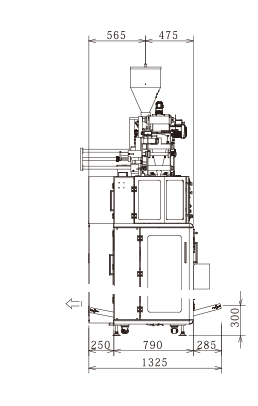

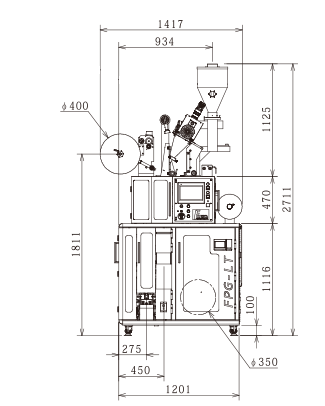

Layout

■FPG-LT with Auger Filler (Optional)

Righit side view

Front view

| Inner Bag Packaging Section | Packaging Method | 3-Side Ultrasonic Sealing and Cutting |

| Measurement Method | Standard: Slide Doser Weighing Option: Load-Cell Weigher, Auger Filler |

|

| Packaging Materials | Nylon, Non-Woven Fabric, and any suitable filters for ultrasonic sealing | |

| Filter Width | 120–200 mm | |

| Bag Size | Rectangular: 45–65 (W) x 60–90 (L) mm Drip bag: 90 x 65–83 mm |

|

| Overwrapping Section | Packaging Method | 3-Side Heat Sealing |

| Packaging Materials | Laminated Film (PP, PE, etc.) | |

| Film Width | 140–220 mm | |

| Overwrap Size | Overwrap (for Rectangular): 70–100 (W) x 85–120 (L) mm Overwrap (for Drip Bag): 100–110 (W) x 120–135 (L) mm |

|

| Capacity | Max. 60 bags/min. | |

| Dimensions | 1,340 (W) x 1,140 (D) x 2,915 (H) mm | |

| Weight | 880 kg | |

| Power Supply * | 3-Phase / 200 V / 2.2 kW | |

| Compressed Air * | 320 L/min. (6 bar) | |

| CE Marking ** | Optional | |

* Transformer for local voltage and dried compressed air to be prepared by the customer.

** Fail-safe design based on CE directive.

Based on 0 reviews

Be the first to review “FPG-LT Coffee Bag with Gas-filled Overwrap Packaging Machine” Cancel reply

Related products

-

Packaging Material, Tea & Coffee

PLA Mesh (NeoSoilon®)

0 out of 5(0)Mesh type | Tea bag material

Launched in January 2020, NeoSoilon® is a 100% PLA mesh filter made from 100% non-GMO sugar cane.

NASA Corporation has supplied PLA-based teabag filters ― Soilon® for more than a decade. PLA (polylactic acid) is a polymer resin made by the lactic fermentation of glucose which is derived from corn starch. The demand for this biodegradable material has grown as the tea industry moves away from petroleum-based materials such as Nylon or PET to avoid environmental harm. Soilon® is woven fabric made from 100% PLA material. Tea bags made with Soilon® are see-through and have good extractability.

Meanwhile, there has been growing consumer demand for organic products in the world, and there has been a newer push for this plant-based material to also be free of GMOs. In response to this, NASA Corporation launched NeoSoilon® in January 2020, a mesh filter for teabags made from 100% non-GMO sugar cane, establishing the world’s largest stable supply system of non-GMO plant-based filters.

As NeoSoilon® is a PLA tea bag filter made from non-GMO plant based material, it is the best packing material for organic tea, allowing for completely certified organic tea products. We hope that NeoSoilon® can set a new standard for teabag filters, promoting a healthy lifestyle and environment for all.

SKU: n/a -

Packaging Machines, Tea & Coffee

FP-CS Tea Bag Packaging Machine

0 out of 5(0)Option

●Weighing System (Load-Cell Weigher, Auger Filler etc.)

●Poking Device for Sub-Hopper

●Slide Doser Vibrator

●Chute Knocking Device

●Multiple Feeding Device for Long Bags

●Acrylic Cover for Packaging Material Roll

●Various Size of Chutes (120 mm, 140 mm, 160 mm, 180 mm etc.)SKU: n/a -

Packaging Material, Tea & Coffee

Large Type Pachit

0 out of 5(0)Pour-over coffee filters | One-cup coffee filters

Pachit drip coffee filter bag is portable and simple to use.

New large type Pachit coffee bag /O3R is now possible to be filled with

over 1/2 oz of ground coffee.

Best matches standard mug sizes for coffee lovers!

Roll type is available for auto-packing, and pre-made bag type for

manual packing by hand.SKU: n/a

There are no reviews yet.